Does your business require uniform sanding of metal or wood parts? Are you planning to automate your work processes and, at the same time, improve the consistency and uniformity of your products? The heavy duty automatic triangular stroke belt sander and polisher (PMCTA) could be the perfect solution to give you complete control over pressure, movement, and sanding time. It allows you to adjust the speed and settings to achieve a product that suits your specific needs.

The triangular PMCTA sander is a heavy-duty industrial piece of equipment designed for the metal fabrication sector. It will surely simplify your sanding and polishing operations and ensure greater product conformity.

If you are currently using an automated carriage sander, you may experience consistency and conformity issues from one part to the next. One operator cannot maintain the same consistency of movement and pressure over a large area and for a large range of products. Thus, there will absolutely be disparities in the part’s appearance and finish. The PMCTA stroke belt sander provides consistency and allows for more accurate adjustments creating a better finish.

During my professional career, I have tested many types of sanding equipment and I have seen the challenges that you face daily, in terms of both the quality of the finished product and recruiting skilled workers. With over 30 years of work experience in the industry, I have frequently had to advise clients on how to optimize their production.

In this article, I present to you to all the factors that need to be considered if you are thinking of purchasing a stroke belt sander. I also answer the questions that I often get from clients, which will help you get an accurate portrait of this piece of equipment that has the capacity to greatly facilitate your production.

TABLE OF CONTENTS

- Who is the PMCTA made for?

- What are the problems/issues/situations that lead the customer to purchase a PMCTA?

- What are the customer's main questions in the process of buying a PMCTA?

- Advantages and disadvantages

- Comparisons with other options?

- The difference between a Doucet PMCTA and the competition’s

- Cost

Who is the PMCTA made for?

Given its flexibility and ease of use, the PMCTA is a must for many businesses in the metal and wood industry. Mainly used for sanding stainless steel parts, these sanders are very useful to reduce the employee’s scope of work and, at the same time, speeding up and uniformizing the results obtained. These sanders can also be used for sanding large surface wood panels.

The PMCTA is different from its counterparts, the PMC and PMCT, in the fact that it is designed for businesses with larger production volume. Entirely automated, it requires few manual interventions in the process, ensuring better predictability and uniformity of the finished product. The result does not depend on the worker’s ability, on the pressure to which the piece is submitted or on the sanding speed.

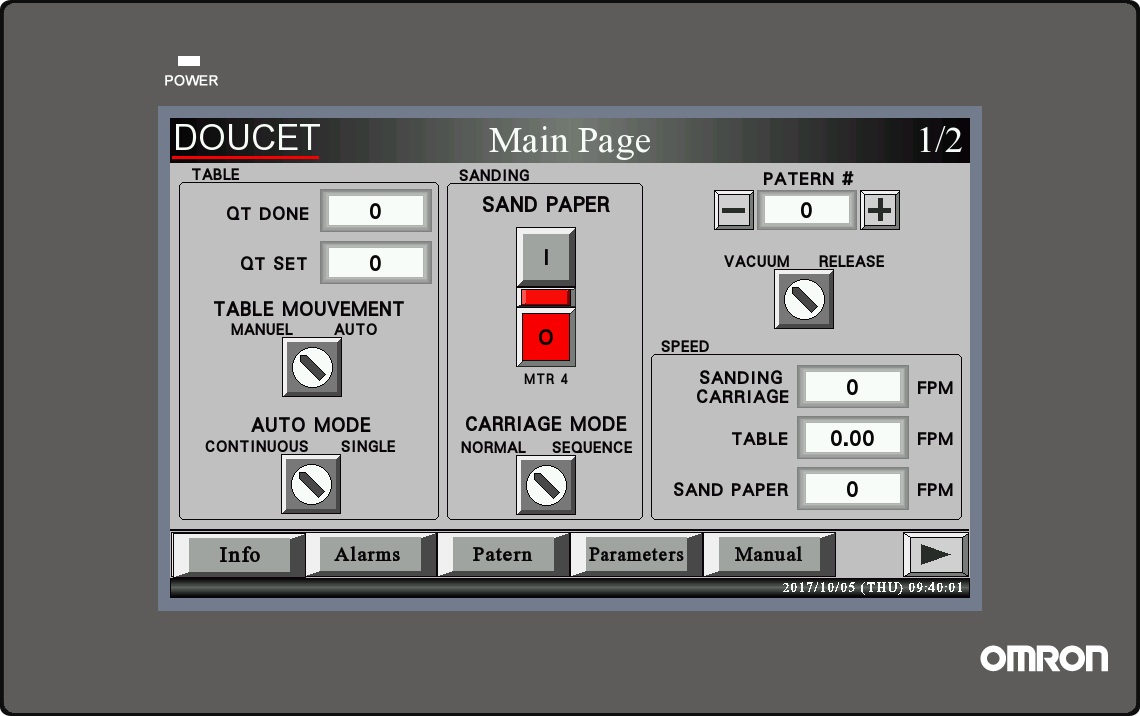

Thus, it is possible for users to enter specific settings on the PMCTA's digital control panel to achieve an optimal finish, no matter how many products are needed.

The PMCTA can handle parts up to 8 feet (96 inches) wide by 4 feet (48 inches) deep and up to 12 feet (144 inches) wide by 5 feet (60 inches) deep.

It is primarily designed for businesses operating in the metal field, more particularly in the following sectors:

- Stainless steel (countertops, sinks, furniture, etc.).

- Aluminium (aeronautics, automotive, pharmaceuticals, food, etc.).

- Preparation of equipment for the next steps e.g.: speaker box or electrical box.

Considering the investment required to acquire the PMCTA, it would however not be recommended for businesses that do not have a large volume of parts to sand. It is possible to consider other types of sanding machines which are less expensive and more suited to the requirements of such businesses. In such a case, the PMCT model (triangular sander with carriage) could be considered.

There are also certain uses for which PMCTA model carriage sanders are not suitable, such as work on small parts that makes clamping to the table challenging or for projects requiring ultra-fine precision.

What are the problems/issues/situations that lead the customer to purchase a PMCTA?

To speed up and standardize production

The use of the PMCTA makes it possible to produce a larger quantity of pieces than manual sanding does. Its characteristics also make it possible to obtain a more uniform product since the operator can adjust the functions of the automatic equipment in such a way as to apply the same amount of pressure and abrasives to the various parts. This provides a more consistent product, even when processing large parts.

Difficulty in recruiting workers

Since it is both programmable and self-contained, the PMCTA allows operators to do other tasks while the machine is completing the project. This saves time and requires less operator specialization. Thanks to the PMCTA, it is also possible to rotate personnel so as not to keep the same person at the same position all the time. This characteristic provides for more varied and value-added jobs.

In a difficult recruiting context, it is essential to provide workers with value-added positions instead of being limited to repetitive tasks. Thus, it is possible to propose more fulfilling tasks to workers.

Product description, specs, features and options

The PMCTA-HD is a heavy-duty automatic triangular stroke belt sander and polisher with a vertical motorized table operating at 3.7 feet per minute.

Learn more about the technical specifications and options for the PMCTA.

What are the customer's main questions in the process of buying a PMCTA?

What are the table sizes offered?

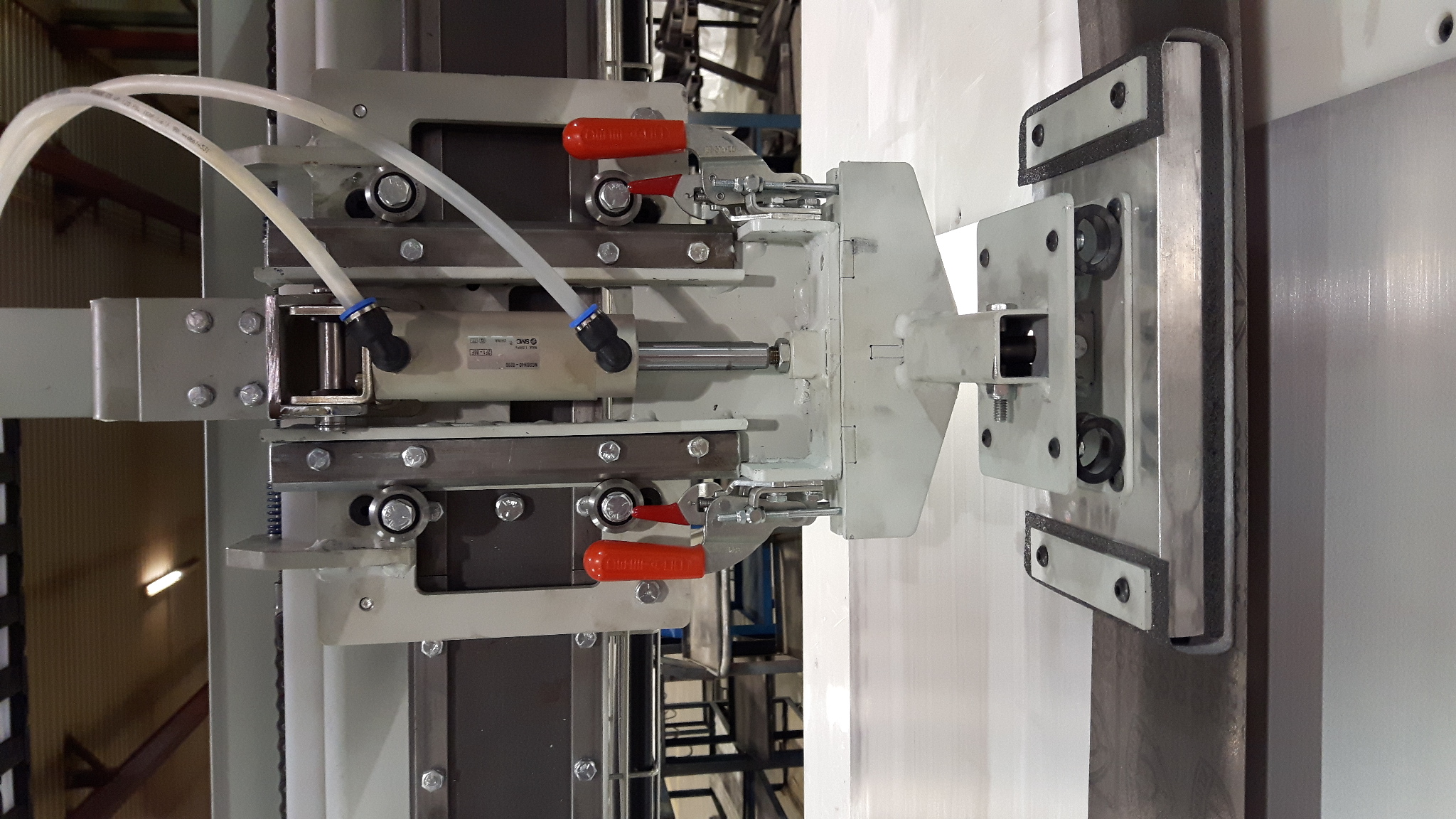

The PMCTA triangular automatic carriage polisher is available in three different table sizes: 96 inches (8 feet), 120 inches (10 feet) and 144 inches (12 feet). You can also choose a table with vacuum cups to hold the components, including:

- 6 integrated vacuum cups

- 1 vacuum generator per venturi

- 1 on/off selector for the vacuum cups

Can we keep track of the different programs?

Yes, you can save the various programs on the control panel and access them by using an alphanumerical code. This allows you to return to a previous setting quickly to get the same finish (same pressure and sanding speed) as in a previous setting.

What are the benefits of having two belts?

Based on the job, you may require two different grades of sandpaper. The two belts allow you to use two grades of paper in the same program, which saves a lot of time. For instance, you could sand one part of the workpiece more vigorously and get a glossier or smoother finish on another part in the same program.

Also, the second belt significantly increases the installation’s productivity in addition to improving the constancy of your final product.

Its advantages and disadvantages

Advantages

The PMCTA is equipped with an interchangeable pressure tool to suit the nature of the work to be performed, which reduces handling and improves efficiency.

The various programs that are entered on the PMCTA's digital panel can be saved and marked with an alphanumeric code or encoded in a database and recovered using a simple bar code. The user is then able to select the proper program for a particular project and operate the sander at the required speed, motion, and pressure settings.

T

he PMCTA is entirely automated, therefore, the operator can do another task while the automatic carriage sander is doing its job.

Disadvantages

The PMCTA is quite expensive, which may be a barrier for businesses that don't have regular sanding operations.

The cart table is relatively large, which requires a good amount of floor space.

Comparisons with other options?

While it may be possible to use wide belt sanders to sand wood or metal parts (if they are in the direction of the grain), few pieces of equipment permit the automatic sanding of parts larger than 48 inches. The PMC-PMCT-PMCTA range of equipment is about the only one able to process this size of material and the technology allows to work them both in the grain direction and perpendicularly.

The difference between a Doucet PMCTA and the competition’s

The PMCTA has only a few competitors. In fact, it has none in America. Only Germany has a business that offers comparable automated sanding machines.

However, this equipment is more expensive, and it may be hard to get a good after-sales service. In fact, because the business has few sales on the continent, it doesn't provide maintenance and repairs in the area. It can also be hard to get answers to questions due to the time zone differences and the language barrier.

Some Asian manufacturers are offering carriage sanders, but they are generally more basic, of lesser quality, and are not automated.

Doucet also has other automated equipment that can compete with the PMCTA, but that are designed for other uses. The APP, a sander with removable sanding head, was developed to process heavier and thicker metal parts, as well as the LPP, which can sand parts up to 25 feet in length.

Cost

- What are the factors affecting the total price? The main factor that influences the cost of the PMCTA is its capacity. It comes in three different sizes ranging from 8 to 12 feet long by 30 to 60 inches deep. The addition of options such as a polishing wheel, as well as a second belt will also have an impact on the price.

- Which sub-factors affect costs? Delivery, equipment installation and on-site worker training are all factors to be considered in developing the total budget for a PMCTA acquisition.

- How much will it cost to buy a PMCTA? The base cost ranges between $67,000 and $90,000 based on the size of the piece of equipment. The addition of vacuum cups, an extra belt or polishing tools will raise the cost by anywhere between $3,000 and $12,000 according to the options selected.

- Turn-key: Doucet's design, manufacturing and installation services are always offered on a turn-key basis. However, certain fees are not part of the selling price and will vary according to the installation.

- Maintenance Fees: Maintenance fees for the PMCTA are minor. The piece of equipment doesn't have any parts that could wear out quickly. If the sander is equipped with a dust collector and the work environment is clean, there is no specific maintenance to be done. In fact, the only replacement needed is for the sandpaper, which is a basic part of all sanding operations.

If metal part sanding is part of the production line of your business, chances are that the PMCTA constitutes a must-have investment. It will increase your productivity, as well as the uniformity of your final products. The fact that this equipment is programmable will also enable you to switch from one adjustment to the next quickly, which is great if you are doing various types of products.

Most importantly, the Doucet automated carriage sander will reduce the handling of various materials, which adds value to your workers' jobs, not to be neglected in the context of labor shortages. While this equipment is running, your operators can do other tasks, ensuring greater profitability.

In fact, in my years of working with businesses like yours, I have observed how quickly the return on investment is achieved with the addition of this piece of equipment. That is not counting the savings in terms of human resources management and health and security in the workplace.

You can purchase it with complete confidence and the assurance that you'll benefit from quick and customized service because this piece of equipment is conceived, made, and distributed in Quebec. We are specialized in the design, manufacturing, and installation of innovative sanding equipment for wood and metal transformation businesses, and we are known for being very flexible.

All the products we offer are designed to perfectly fit your requirements and your working environment. They are all installed by one of our team of experts.

The next step is to test your materials and see the results. There is nothing better than to see that each action will improve the result and your production efficiency. Doucet is a North American leader in design, manufacturing, and integration of advanced solutions for wood and metal processing companies. Contact us for more information!

For your convenience we have 3 ways to contact us:

- Complete the “Request a quote” form online.

- Via Email: info@doucetinc.com

- Or call us at: 1-866-673-8876